HR series horizontal two-stage piston pusher centrifuges are widely used in industries such as chemical engineering, fertilizer production, soda ash production, salt production, pharmaceuticals, food, and light industry. They are particularly suitable for solid-liquid separation of substances like sodium chloride, ammonium chloride, ammonium bicarbonate, sodium sulfate, and urea.

Introduction:

The horizontal two-stage piston pusher centrifuge is a type of horizontal two-stage piston pusher and continuous operation filtration centrifuge. Can continuously feed, separate, wash, discharge and other processes under full operation. It features continuous operation, smooth running, high separation factor, large production capacity, high output, good washing effect, low moisture content of filter cake and low solid content of mother liquor. This machine is suitable for separating suspensions of crystalline and fibrous materials with medium particles, especially for materials that need to be washed inside the machine. However, it is required that the feed concentration be stable and the feeding be uniform. Materials with a solid content in the suspension ranging from 20% to 40%, a solid particle size within the range of 0.05 to 3mm, and a suspension temperature not exceeding 80 degrees can all be separated normally.

Working principle:

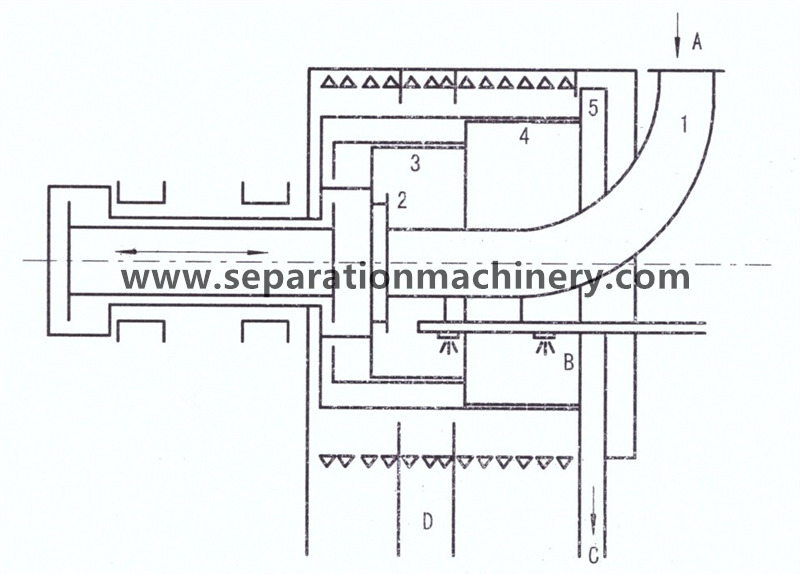

After the drum 3 rotates at full speed, the suspension to be separated continuously enters the circular distribution disc 2 installed on the outer drum 4 through the feed pipe 1. Under the action of centrifugal force, the suspension is uniformly thrown along the circumference onto the screen installed inside the drum 3. Most of the liquid phase is thrown out of the drum through the screen mesh and the holes on the inner drum wall, while the solid phase is retained on the screen to form a ring-shaped filter residue layer. The filter residue is pushed forward a certain distance along the axial direction of the drum by the return stroke of the drum. When the inner drum progresses, a new layer of filter residue is formed on the empty screen surface. With the reciprocating motion of the inner drum, the filter residue layers are pushed forward successively and further dried. Finally, the filter residue is pushed to the outer drum 4. After the filter residue becomes loose, it is re-distributed, allowing the filter residue to be further dried in the outer drum Finally, the filter residue is pushed out of the outer drum and enters the collection trough 5. Through the scraper installed on the outer drum, the filter residue is discharged outside the machine from the tangential direction through the discharge port of the casing. If the filter residue needs to be washed inside the machine, the washing liquid is continuously distributed on the filter residue house through the washing pipe or other flushing equipment. The separated mother liquid along with the washing liquid is collected in the machine casing and discharged through the liquid outlet. When the customer has special requirements, the mother liquid and the washing liquid can also be collected and discharged separately.

Application scope:

HR series horizontal two-stage piston pusher centrifuges are widely used in industries such as chemical engineering, fertilizer production, soda ash production, salt production, pharmaceuticals, food, and light industry. They are particularly suitable for solid-liquid separation of substances like sodium chloride, ammonium chloride, ammonium bicarbonate, sodium sulfate, and urea.

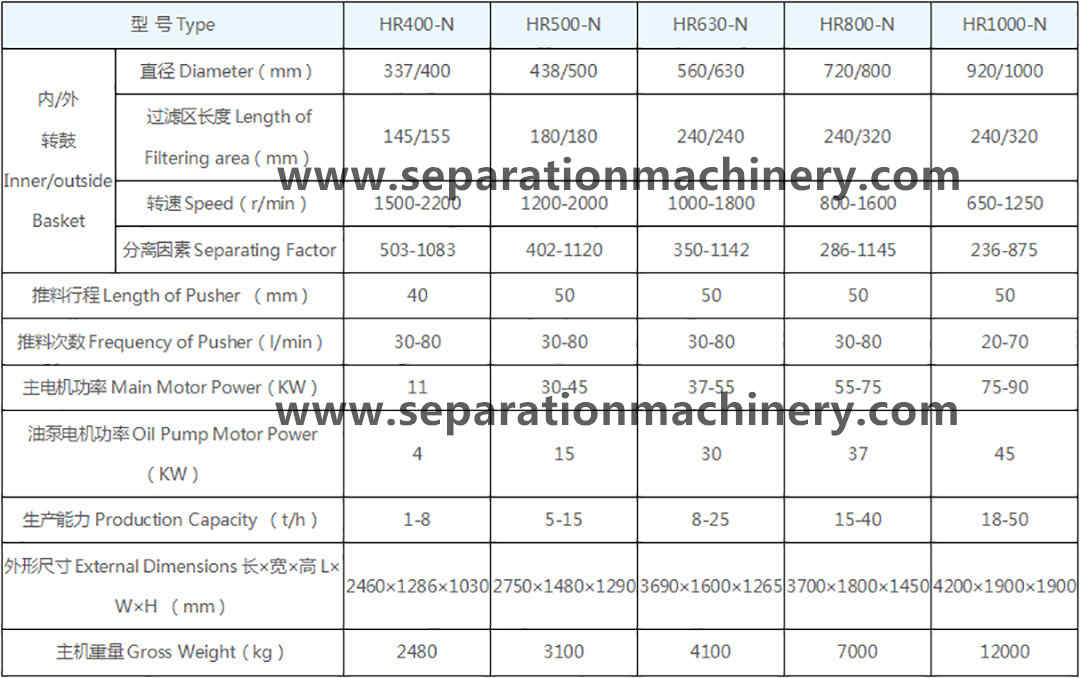

Technical parameters: