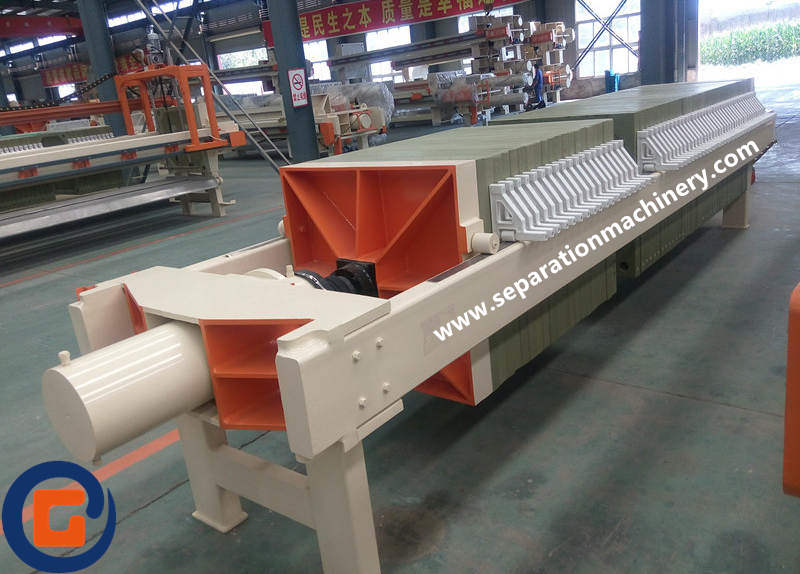

Polypropylene Membrane Mining Filter Press Machine For Russia adopts international advanced TPE membrane technology, so that ensure stable performance and long life-span, and widely used for various industries.

Introduction of Filter Press

Polypropylene Membrane Mining Filter Press Machine For Russia adopts international advanced TPE membrane technology, so that ensure stable performance and long life-span, and widely used for various industries.

Cake from membrane filter press can be secondarily squeezed under max 1.6MPa by water to realize the lowest cake residual moisture. In some wastewater treatment industries, the final cake can be used for landfill or burning directly.

The membrane filter press can realize fully automatic operation with flexible devices, such as: belt conveyor, drip tray, cloth washing system, etc.

Working principle of Membrane Filter Press

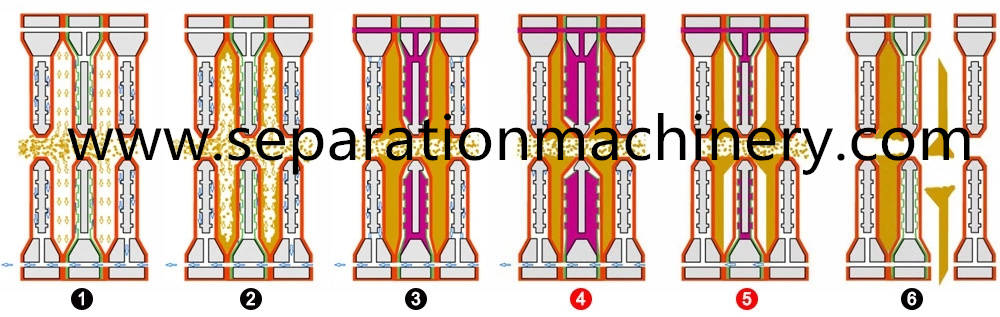

1.Feeding: Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

2.Filtration: Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

3.Filtration completed: When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

4.Membrane Squeezing: Once the chambers are full, the fill cycle is over, high pressure water or compressed air will start fill in between membranes of filter plates, pushing the membrane toward the filter cakes, squeezing the filter cakes to remove any residue water.

5.Pressure relief: when squeezing is over, high pressure water(compressed air) is released from between the membranes.

6.Cake discharge: after pressure relived, the filter press is ready to discharge cakes.

(* Note: 4, 5 is only for membrane filter press)

The filter plates of membrane type filter press consists of two kinds filter plates: membrane filter plate (whose surface is flat) and chamber plate (which as depth for filter cake storage). The filtering process as following. Under the pressure of feeding pump, material is pumped into filter chamber, solid and liquid are separated by filter medium (filter cloth). After filter cakes formed, the compressed air will be blown into the membrane plate and inflate it to squeeze cake, thus realize lower moisture. Membrane filter press specially applies to viscous material and users who require a strict cake dryness.

Filter plates are made from reinforced PP by mould pressing. Membranes are recessed with PP plates integrally. They are firm and steady, not easy to fall off, and enjoy long.

Advantages of Membrane Filter Press

1. Low cake moisture

2. Unmanned operation and cost saving

3. Resist high temperature and corrosion

4. Good sealing effect can perfectly avoid leskage

5. Can realize twice squeezing (first squeeze by filter press, second squeeze by air or water)

Application of membrane filter press

Automatic membrane filter perss specially apply to easy volatile, toxic, Irritating material or mining industry, or users who request good operating environment and low cake moisture.

Technical Parameters

| Model | Filter area (m2) | Plate size (mm) | Cake thickness (mm) | Filter chamber volume (L) | Number of plates (pcs) | Filtration pressure (MPa) | Motor power (Kw) | Total weight (kgs) | Overall dimension LxWxH (mm) |

| XGZ30/870-U | 30 | 870×870 | <= 35 | 498 | 23 | >=0.8 | 2.2 | 3046 | 3880*1250*1300 |

| XGZ40/870-U | 40 | 623 | 30 | 3593 | 4270*1250*1300 | ||||

| XGZ50/870-U | 50 | 789 | 38 | 4057 | 4790*1250*1300 | ||||

| XGZ60/870-U | 60 | 955 | 46 | 4597 | 5310*1250*1300 | ||||

| XGZ70/870-U | 70 | 1121 | 54 | 5136 | 5830*1250*1300 | ||||

| XGZ80/870-U | 80 | 1287 | 62 | 5636 | 6350*1250*1300 | ||||

| XGZ50/1000-U | 50 | 1000×1000 | <=35 | 776 | 28 | >=0.8 | 4 | 4352 | 4270*1500*1400 |

| XGZ60/1000-U | 60 | 943 | 34 | 4480 | 4770*1500*1400 | ||||

| XGZ70/1000-U | 70 | 1109 | 40 | 5263 | 5130*1500*1400 | ||||

| XGZ80/1000-U | 80 | 1275 | 46 | 5719 | 5560*1500*1400 | ||||

| XGZ100/1000-U | 100 | 1608 | 57 | 6555 | 6410*1500*1400 | ||||

| XGZ120/1000-U | 120 | 1941 | 69 | 7466 | 7260*1500*1400 | ||||

| XGZ80/1250-U | 80 | 1250x1250 | <= 40 | 1560 | 29 | >=0.8 | 5.5 | 10900 | 4830*1800*1600 |

| XGZ100/1250-U | 100 | 1975 | 37 | 11750 | 5440*1800*1600 | ||||

| XGZ120/1250-U | 120 | 2391 | 45 | 12600 | 6060*1800*1600 | ||||

| XGZ150/1250-U | 150 | 2911 | 55 | 13620 | 6820*1800*1600 | ||||

| XGZ160/1250-U | 160 | 3119 | 59 | 14470 | 7130*1800*1600 | ||||

| XGZ200/1250-U | 200 | 3847 | 73 | 15320 | 8200*1800*1600 | ||||

| XGZ240/1250-U | 240 | 4679 | 89 | 16170 | 9420*1800*1600 | ||||

| XGZ250/1250-U | 250 | 4783 | 91 | 17020 | 9570*1800*1600 | ||||

| XGZ200/1500-U | 200 | 1500x1500 | <=40 | 3809 | 49 | >=0.8 | 11 | 26120 | 7140*2200*1820 |

| XGZ250/1500-U | 250 | 4723 | 61 | 26930 | 7730*2200*1820 | ||||

| XGZ300/1500-U | 300 | 5637 | 73 | 28160 | 8720*2200*1820 | ||||

| XGZ350/1500-U | 350 | 6551 | 85 | 29600 | 10110*2200*1820 | ||||

| XGZ400/1500-U | 400 | 7618 | 99 | 31500 | 11260*2200*1820 | ||||

| XGZ450/1500-U | 450 | 8532 | 111 | 33400 | 12250*2200*1820 | ||||

| XGZ500/1500-U | 500 | 9446 | 123 | 33380 | 13240*2200*1820 | ||||

| XGZ600/2000-U | 600 | 2000x2000 | <= 40 | 11901 | 85 | >=0.8 | 15 | 54164 | 13030*3000*2500 |

| XGZ700/2000-U | 700 | 13838 | 99 | 58300 | 14390*3000*2500 | ||||

| XGZ800/2000-U | 800 | 14945 | 107 | 62460 | 15770*3000*2500 | ||||

| XGZ900/2000-U | 900 | 17713 | 127 | 66620 | 17150*3000*2500 | ||||

| XGZ1000/2000-U | 1000 | 19651 | 141 | 70780 | 18530*3000*2500 |