In the modern industrial and environmental protection fields, the oil-water separation tubular separator, as an efficient and precise liquid-liquid-solid separation solution, is playing an increasingly important role.

Introduction:

In the modern industrial and environmental protection fields, the oil-water separation tubular separator, as an efficient and precise liquid-liquid-solid separation solution, is playing an increasingly important role.

The Application:

1) Food processing: In the food industry, oil-water separators are often used for the oil-water separation of some animal and vegetable oils, such as fish oil, shrimp oil, chicken oil and other animal oils and water separation, as well as the oil-water residue separation of bone broth made by boiling.

2) Feed processing industry: oil-water separation of kitchen waste oil, oil-water separation in animal organ treatment, etc.

3) Refining of vegetable oils: Processing of Sichuan pepper oil, sea buckthorn oil, cold-pressed coconut oil, avocado oil, and extraction of some essential oils such as rose essential oil and citrus oil;

4) Purification and recovery of oil products: Recovery processes for lubricating oil, inverter oil, engine oil, etc.

5) Chemical industry: Separation between two immiscible liquids with a specific gravity difference.

Working principle:

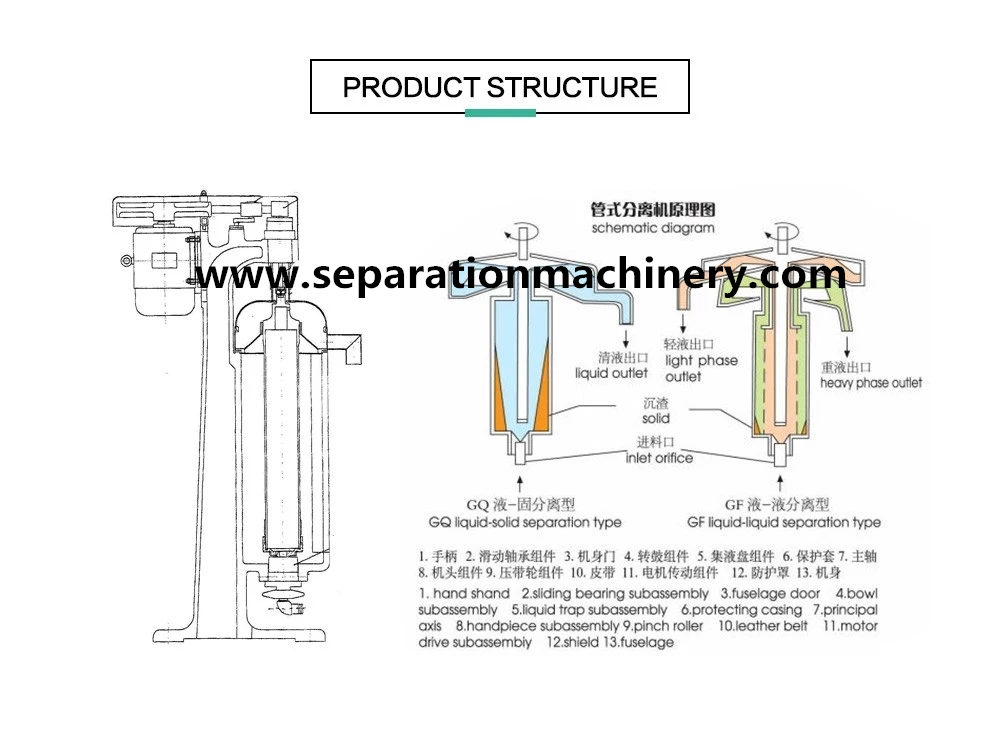

The oil-water separation tubular separator is a type of GF tubular centrifuge, which is a high-speed centrifugal separation equipment designed based on the principle of centrifugal force. Its core component is the drum, which is tubular in shape, has a small diameter but a large length, and rotates at an extremely high speed. When the emulsion (such as an oil-water mixture) enters from the lower end of the drum, it is driven by the longitudinal stiffening plates inside the drum to rotate at the same speed as the drum. Under the action of centrifugal force, different components in the emulsion separate rapidly. The heavy liquid layer (such as water) leans towards the wall of the drum, while the light liquid layer (such as oil) leans towards the center of the drum. These two layers of liquid flow respectively along the length of the drum and are eventually discharged from the corresponding overflow outlets at the top of the drum, achieving efficient separation. If the emulsion contains tiny solid particles, the solids will also be separated in the drum at the same time and removed when the machine stops.

Technical Parameters:

| Model | Unit | GQ/GF45 | GQ/GF75 | GQ/GF105 | GQ/GF115 | GQ/GF125 | GQ/GF150 |

| Bowl Diameter | mm | 45 | 75 | 105 | 115 | 125 | 150 |

| Bowl Speed | r/min | 10000-30000 | 19000 | 16300 | 16300 | 15000 | 13400 |

| Separation factor | -- | 19800 | 15200 | 15620 | 17000 | 15700 | 14300 |

| Bowl Volume | L | 0.45 | 2.2 | 6 | 7 | 8 | 10 |

| Throughput Capacity | L/H | 100 | 600 | 1200 | 1300 | 1500 | 2500 |

| Motor | kw | 0.55 | 1.5 | 2.2 | 3.0 | 3.0 | 3.0 |

| Weight | kg | 90 | 260 | 500 | 520 | 530 | 600 |

| Dimension(L*W*H) | mm | 500*420*760 | 760*450*1120 | 550*850*1600 | 600*900*1600 | 650*950*1600 | 700*1000*1600 |