The pharmaceutical manufacturing industry tubular centrifuge, in response to the characteristics of biological products such as high viscosity, small volume and difficulty in separation, has been improved on the basis of the original general-purpose centrifuge to increase the yield and output.

Introduction:

The pharmaceutical manufacturing industry tubular centrifuge, in response to the characteristics of biological products such as high viscosity, small volume and difficulty in separation, has been improved on the basis of the original general-purpose centrifuge to increase the yield and output. Due to the requirements of different biological processes, in-situ sterilization, cooling of the machine body coil to ensure that the material temperature does not rise and real-time monitoring of temperature changes can be achieved according to the user's requirements. Nitrogen protection can also be provided, etc.

The Application:

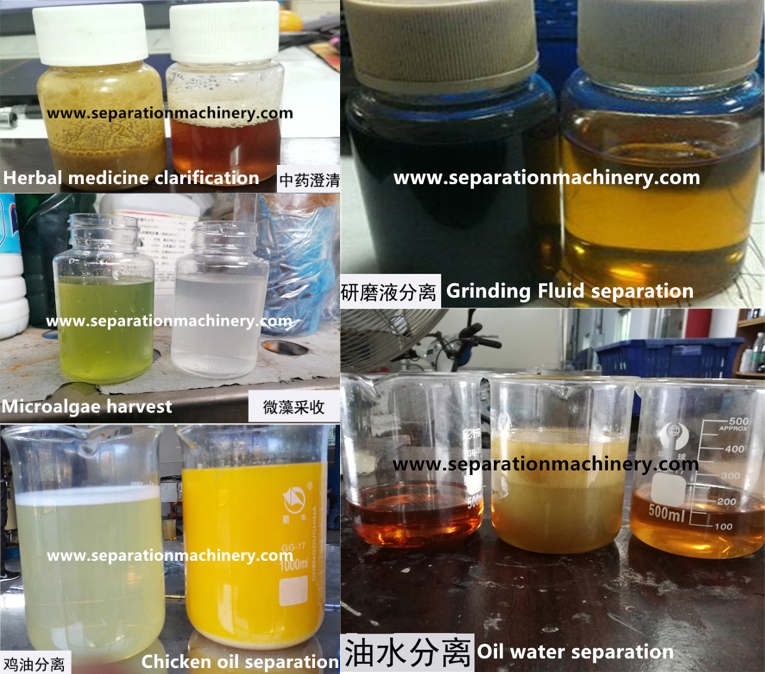

1) Biotechnology industry: In the field of biotechnology, biological tubular centrifuges are used for the production of biomolecules such as proteins and enzymes, the separation and collection of various microbial fermentation liquids, and the extraction of algae, etc.

2) Pharmaceutical manufacturing industry: The pharmaceutical industry needs to separate various chemical substances, drugs and vaccines, etc. Traditional chemical separation techniques often fail to achieve the desired separation effect. However, biological tubular centrifuges have become the preferred equipment in the pharmaceutical industry due to their high efficiency and the fact that the separation process does not require a filtering medium.

3) Environmental engineering industry: In addition, biological tubular centrifuges can also be used in environmental engineering fields such as sewage treatment and organic waste treatment, contributing to environmental protection and sustainable development.

Working principle:

Working principle:

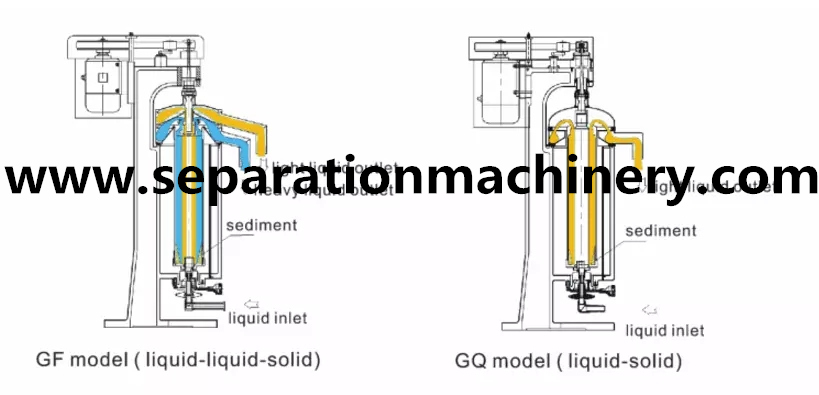

The working principle of the pharmaceutical manufacturing industry tubular centrifuge is based on the principle of centrifugal force separation. When the equipment is in operation, the drum rotates at high speed around its own axis, forming a powerful centrifugal force field. The material is injected into the bottom liquid inlet system through the liquid inlet nozzle. The centrifugal force inside the drum forces the material liquid to flow upward along the inner wall of the drum. Due to the density difference of different compositions of the material liquid, it stratifies. This separation effect enables substances with different sedimentation coefficients and buoyant densities to be effectively separated.

Technical Parameters:

| Model | Unit | GQ/GF45 | GQ/GF75 | GQ/GF105 | GQ/GF115 | GQ/GF125 | GQ/GF150 |

| Bowl Diameter | mm | 45 | 75 | 105 | 115 | 125 | 150 |

| Bowl Speed | r/min | 10000-30000 | 19000 | 16300 | 16300 | 15000 | 13400 |

| Separation factor | -- | 19800 | 15200 | 15620 | 17000 | 15700 | 14300 |

| Bowl Volume | L | 0.45 | 2.2 | 6 | 7 | 8 | 10 |

| Throughput Capacity | L/H | 100 | 600 | 1200 | 1300 | 1500 | 2500 |

| Motor | kw | 0.55 | 1.5 | 2.2 | 3.0 | 3.0 | 3.0 |

| Weight | kg | 90 | 260 | 500 | 520 | 530 | 600 |

| Dimension(L*W*H) | mm | 500*420*760 | 760*450*1120 | 550*850*1600 | 600*900*1600 | 650*950*1600 | 700*1000*1600 |