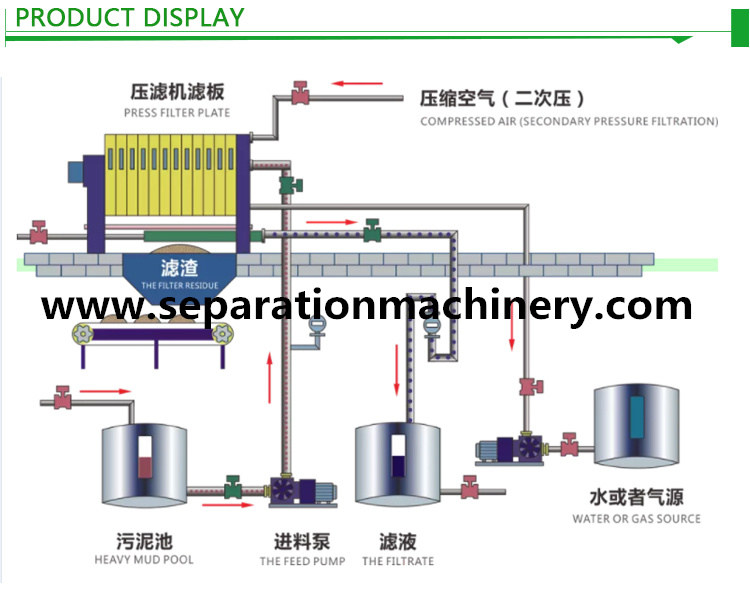

The filter plates of membrane type filter press consists of two kinds filter plates: membrane filter plate (whose surface is flat) and chamber plate (which as depth for filter cake storage). The filtering process as following. Under the pressure of feeding pump, material is pumped into filter chamber, solid and liquid are separated by filter medium (filter cloth). After filter cakes formed, the compressed air will be blown into the membrane plate and inflate it to squeeze cake, thus realize lower moisture. Membrane filter press specially applies to viscous material and users who require a strict cake dryness.

Introduction of Membrane Filter Press:

The filter plates of membrane type filter press consists of two kinds filter plates: membrane filter plate (whose surface is flat) and chamber plate (which as depth for filter cake storage). The filtering process as following. Under the pressure of feeding pump, material is pumped into filter chamber, solid and liquid are separated by filter medium (filter cloth). After filter cakes formed, the compressed air will be blown into the membrane plate and inflate it to squeeze cake, thus realize lower moisture. Membrane filter press specially applies to viscous material and users who require a strict cake dryness.

Filter plates are made from reinforced PP by mould pressing. Membranes are recessed with PP plates integrally. They are firm and steady, not easy to fall off, and enjoy long.

Main components of membrane filter press:

> Frame: The steel frame acts as a clamping device for the filter plates.

> Filter Plates: A filter cake forms in the chambers between filter plates.

> Filter Cloth: A cloth filter that is attached to both sides of a filter plate. Solids build up on cloth to form a filter cake, separating liquids from solids.

Working principle of Automatic Operating Membrane Filter Press:

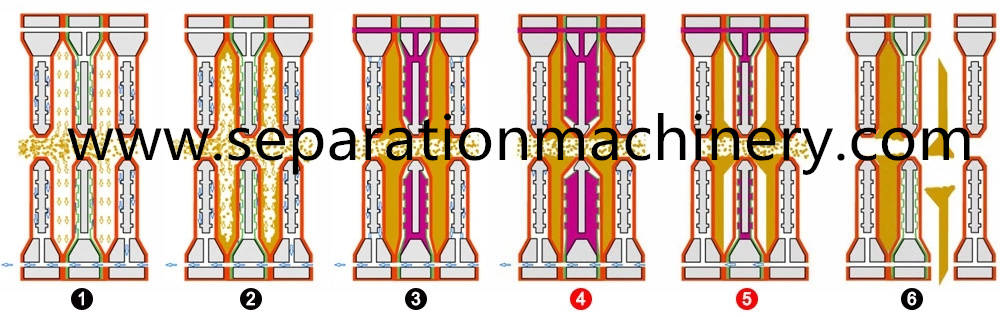

1.Feeding: Slurry is pumped into the filter press. The solids are distributed evenly on the filter cloths during the feed (fill) cycle.

2.Filtration: Solids begin to build on the filter cloth, trapping the ensuing particles and building a filter cake. The filter cake acts as a depth filter for solid/liquid separation. Filtrate exits the plates through the corner ports into the manifold.

3.Filtration completed: When the correct valves in the manifold are open, the filtrate exits the press through the filtrate outlet. As the filter press feed pump builds pressure, the solids build within the chambers until they are completely full of filter cake.

4.Membrane Squeezing: Once the chambers are full, the fill cycle is over, high pressure water or compressed air will start fill in between membranes of filter plates, pushing the membrane toward the filter cakes, squeezing the filter cakes to remove any residue water.

5.Pressure relief: when squeezing is over, high pressure water(compressed air) is released from between the membranes.

6.Cake discharge: after pressure relived, the filter press is ready to discharge cakes.

(Note: 4, 5 is only for membrane filter press)

Types of Filter Press according to:

> Closing mode: manual, gear drive, hydraulic;

> Filtrate flow: open flow, close flow, cake washing, non-cake washing, center feeding, corner feeding,etc..

> Filter plate structure: recessed plate, plate &frame, diaphragm squeeze (membrane) plate;

> Filter plate material: PP, rubber, cast iron, stainless steel;

> Filter Plate size: 320, 450, 630, 800,1000, 1250, 1500, 2000

Filter Plate:

Filter Cloth:

Characteristic of Automatic membrane filter press :

1. Short working cycle and high efficiency: high pressure squeezing, can greatly reduce the water content in cake in a short time.

2. Low operation cost: wholly Automatic program-controlled. This membrane filter press can be working unattended, and saving the operation cost.

3. Simple operation: Adopt upper washing device, with few actions and synchronous with auto plate shifting machine. The washing cycles can be set according to requirements (can be regulated on site).

4. Low power consumption: the diaphragm squeezing function, in a very short time to complete this process, save the power consumption.

5. Widely application: corrosion resistance is strong; basic applies to all solid-liquid separation projects.

6. High pressure squeezing: the TPE elastomer makes the filter plate with good quality and can achieve maximum pressure filter 25 MPA, so that the moisture content is reduced greatly, save drying cost and improve the yield.

7 Automatic drip trays: drip tray also can be added according to customer's needs and auto open & close can be controlled by PLC system.

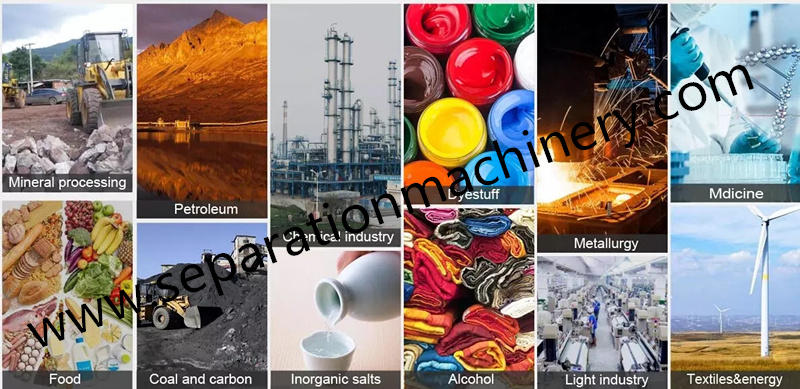

Application of the Automatic membrane filter press:

This automatic membrane filter press is widely applied in petroleum, chemical, metallurgy, environmental protection, food, beverage, pharmaceutical, sugar, starch, paper, coal-washing, ceramics, mineral processing and various sewage treatment industries separation the solid-liquid.

Technical Parameters:

| Model | Filter area (m2) | Plate size (mm) | Cake thickness (mm) | Filter chamber volume (L) | Number of plates (pcs) | Filtration pressure (MPa) | Motor power (Kw) | Total weight (kgs) | Overall dimension LxWxH (mm) |

| XGZ30/870-U | 30 | 870×870 | <= 35 | 498 | 23 | >=0.8 | 2.2 | 3046 | 3880*1250*1300 |

| XGZ40/870-U | 40 | 623 | 30 | 3593 | 4270*1250*1300 | ||||

| XGZ50/870-U | 50 | 789 | 38 | 4057 | 4790*1250*1300 | ||||

| XGZ60/870-U | 60 | 955 | 46 | 4597 | 5310*1250*1300 | ||||

| XGZ70/870-U | 70 | 1121 | 54 | 5136 | 5830*1250*1300 | ||||

| XGZ80/870-U | 80 | 1287 | 62 | 5636 | 6350*1250*1300 | ||||

| XGZ50/1000-U | 50 | 1000×1000 | <=35 | 776 | 28 | >=0.8 | 4 | 4352 | 4270*1500*1400 |

| XGZ60/1000-U | 60 | 943 | 34 | 4480 | 4770*1500*1400 | ||||

| XGZ70/1000-U | 70 | 1109 | 40 | 5263 | 5130*1500*1400 | ||||

| XGZ80/1000-U | 80 | 1275 | 46 | 5719 | 5560*1500*1400 | ||||

| XGZ100/1000-U | 100 | 1608 | 57 | 6555 | 6410*1500*1400 | ||||

| XGZ120/1000-U | 120 | 1941 | 69 | 7466 | 7260*1500*1400 | ||||

| XGZ80/1250-U | 80 | 1250x1250 | <= 40 | 1560 | 29 | >=0.8 | 5.5 | 10900 | 4830*1800*1600 |

| XGZ100/1250-U | 100 | 1975 | 37 | 11750 | 5440*1800*1600 | ||||

| XGZ120/1250-U | 120 | 2391 | 45 | 12600 | 6060*1800*1600 | ||||

| XGZ150/1250-U | 150 | 2911 | 55 | 13620 | 6820*1800*1600 | ||||

| XGZ160/1250-U | 160 | 3119 | 59 | 14470 | 7130*1800*1600 | ||||

| XGZ200/1250-U | 200 | 3847 | 73 | 15320 | 8200*1800*1600 | ||||

| XGZ240/1250-U | 240 | 4679 | 89 | 16170 | 9420*1800*1600 | ||||

| XGZ250/1250-U | 250 | 4783 | 91 | 17020 | 9570*1800*1600 | ||||

| XGZ200/1500-U | 200 | 1500x1500 | <=40 | 3809 | 49 | >=0.8 | 11 | 26120 | 7140*2200*1820 |

| XGZ250/1500-U | 250 | 4723 | 61 | 26930 | 7730*2200*1820 | ||||

| XGZ300/1500-U | 300 | 5637 | 73 | 28160 | 8720*2200*1820 | ||||

| XGZ350/1500-U | 350 | 6551 | 85 | 29600 | 10110*2200*1820 | ||||

| XGZ400/1500-U | 400 | 7618 | 99 | 31500 | 11260*2200*1820 | ||||

| XGZ450/1500-U | 450 | 8532 | 111 | 33400 | 12250*2200*1820 | ||||

| XGZ500/1500-U | 500 | 9446 | 123 | 33380 | 13240*2200*1820 | ||||

| XGZ600/2000-U | 600 | 2000x2000 | <= 40 | 11901 | 85 | >=0.8 | 15 | 54164 | 13030*3000*2500 |

| XGZ700/2000-U | 700 | 13838 | 99 | 58300 | 14390*3000*2500 | ||||

| XGZ800/2000-U | 800 | 14945 | 107 | 62460 | 15770*3000*2500 | ||||

| XGZ900/2000-U | 900 | 17713 | 127 | 66620 | 17150*3000*2500 | ||||

| XGZ1000/2000-U | 1000 | 19651 | 141 | 70780 | 18530*3000*2500 |

FAQ

1, Do you have manual with the machine?

Yes, of course. It is in English version.

2, Can you offer us the necessary paper to do the customs clearance?

Yes, of course. We will send you the commercial invoice, sales contract, packing list, bill of lading(FOB or CFR, CIF terms), insurance policy (if CIF terms), also CO if you need.

3. Can you help us to make our products?

Yes sure we can! OEM is warmly welcomed!

4. What is warrant period for the Machine?

Usually the guarantee period is 1 year, and we will keep contact with our

customers for after-sales service. We're aim to produce better machines and let our customers be satisfied.

5. How can i get quotation?

Just send email with requirement of product and you'll get prompt response from us.

6. If we have problems when using the Machine, what should we do?

If you have any problem, just contact us, we will help you to solve it, and if necessary, we will arrange our engineers to help you in your country.

7. What about the shipping methods?

For urgent order and light weight, you can choose express: FedEx, TNT, DHL or EMS; for heavy weight, you can choose by air or by sea to save cost.